Silica Sand & Silica Powder

Silica Sand & Silica Powder

As a general rule, “The purer the sand, the clearer the products…”

Silicon and oxygen are the earth’s two most abundant elements and together they make silica, one of the earth’s three most common rock forming minerals.

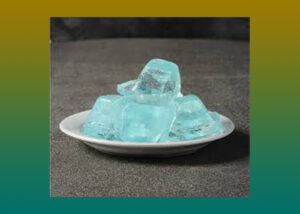

Akshar Minerals Silica sand is high purity natural crystalline silica. It is inherently bright, white, low in moisture and chemically inert in nature. Basically, It is made up of two main element Silica & Oxygen. Silica sand is made up of Silicon Dioxide. There are number of different uses of silica sand in the industrial and commercial sector, from golf courses to glass making .

The chemical formula of Silica Sand is SiO2

Disclaimer : We do not sale any river or seashore sand.

Characteristics :

- High Purity

- Weather Resistant

- White Appearance

- Naturally Hard

- Controlled Particle size

- Chemically Inert

Applications

Akshar Minerals Silica sand is used depends on physical, chemical and mechanical characteristics such as grain size, shape color, structure and distribution as well as refractoriness strength and stability. There characteristics can differ depending on how mineral is processed after it is mined. This product gets easily mixed and can be used for high temperature applications like flat glass, furnace tubes and many more due to its excellent thermal expansion, hardness. It yields improved durability and burnish resistance. We make for all type of application in the industries like Glass industries, Sodium Silicate Industry, Golf course & Sport Ground, Adhesive and sealant, Rubber industry, Texture Wall Paint, Sand Blasting, Agro pesticide, Cosmetic industry, Soap & Detergent, Filtration Media, Power Plant & Petroleum, Construction Chemical Industry, Plastic, Fertilizer, Paint, Ceramic, Insulation, Foundry, Ramming Mass, Steel Industry, Landscaping, GRC & GRP Industry, Oil & Petroleum Industry, Oil Exploration & Oil Drilling.

Silica Sand Gradesheet

| Parameters | AGS- A | AGS-Spiral | AGS-B | AGS-C |

|---|---|---|---|---|

| SiO2 | 99.1 % Min | 99.40% Min. | 98.5 % Min | 99.5 % Min |

| AI2O3 | < 0.2 % | < 0.5 % | < 0.5 % | < 0.2 % |

| Fe2O3 | < 180 ppm | < 180 ppm | < 800 ppm | <150 ppm |

| CaO | < 0.15 % | < 0.15 % | < 0.15 % | < 0.15 % |

| TiO2 | < 0.04 % | < 0.05 % | < 0.05 % | < 0.04 % |

| Moisture | No Moisture | 5% max | 5% max | No Moisture |

| Process | Dry | Wet | Wet and Dry | Dry |

| Grain Size | As Per Requirement | As Per Requirement | As Per Requirement | As Per Requirement |

Silica Sand & Silica Powder

Silica Sand & Silica Powder